Capabilities

See what we can build working together

Soundwich’s team brings together high-end expertise with cutting-edge technology and support to take on your biggest challenges and deliver results. We pride ourselves on being the low-cost provider of thermal acoustical solutions on the market, and our engineers are always excited to find a new angle on an obstacle.

Tooling

Tooling is a critically important and often-overlooked part of a reliable and stable process that produces a quality final product. We balance quality requirements, serviceability and cost while taking into account production volume, life of the program and budgetary and timing constraints. Whatever boundaries you’re working with, our team is ready to develop the right solution for your need.

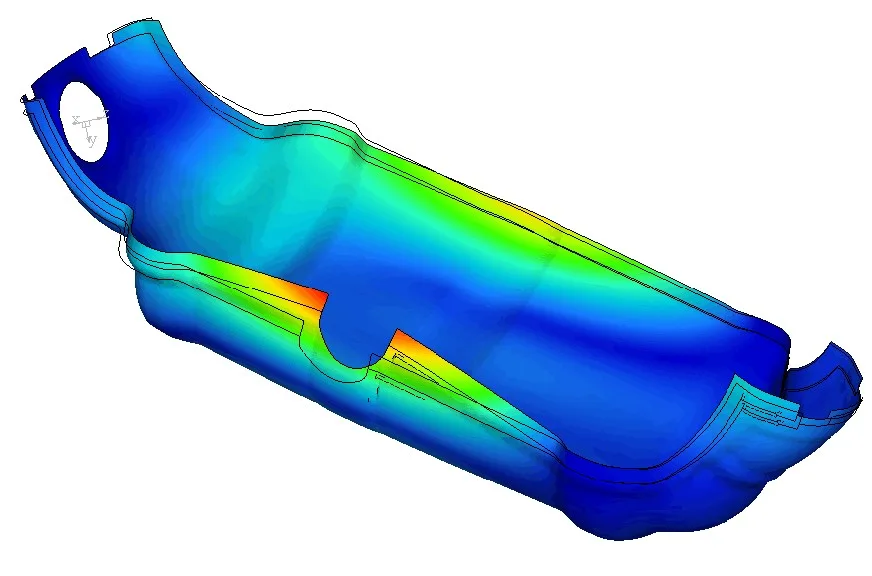

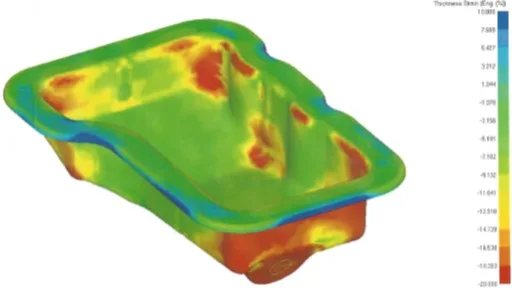

We have the capability and experience to do forming simulations and tool design in-house, keeping the process quick and responsive to your timelines. A fully-equipped and staffed Tool Room on-site allows us to maintain and repair tools as needed. We’ve established relationships with tooling partners in the U.S., North America and around the world to design and build our tools.

Prototyping

We can provide customers with prototyping for any product we sell for production, making us a one-stop shop for testing. The lessons learned from making prototypes get incorporated into production tooling, reducing risk and saving money on the project overall. Our expert staff is ready to work with you to get a prototype developed quickly no matter where you are in your process. Whether it’s early in your development phase and a physical part is needed for validation or production tools won’t be ready for early builds, we have in-house capabilities to meet your needs. Working with Soundwich for testing and prototyping removes the need to manage an additional supplier.

Detailed Prototyping capabilities

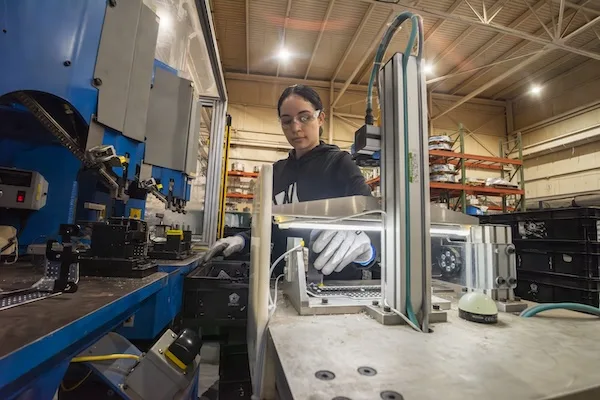

Quality assurance

Building for quality is a part of every step of our processes. We’re proud of our third-party accreditation and certifications, such as IATF 16949, AS 9100D, ISO 9001, IOS14001 and American Welding Society. Our in-house inspection capabilities will save you time and money, building from our expertise with GD&T as well as CMM, optical comparator and attribute gauges for all 3-D formed parts. Testing for PPAP and FAI can be done in our lab or by a third party.

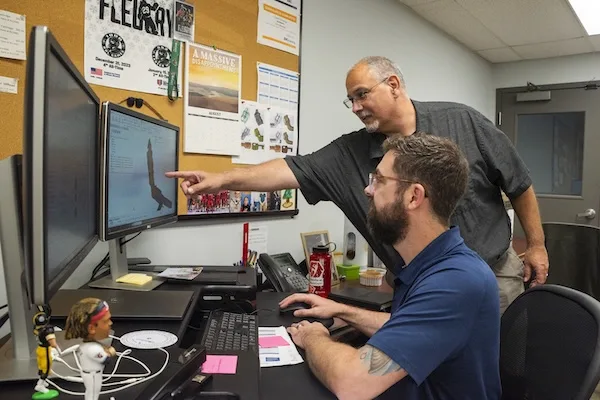

Automotive design, engineering and R&D

Whatever stage of development your project is at, our experienced team is ready to work with and support you at your point of need. When you realize your design needs a heat shield and don’t know where to begin, we’re here to help. We work natively in a wide variety of CAD environments, such as Siemens NX, SolidWorks and AutoCAD. Designs can be tested in simulation and physically either in-house or through a third party for thermal, vibration and corrosion testing as well as manufacturability. Our on-staff material scientists assist in either making the right selections or developing new materials and products to meet your specifications.

Key capabilities and core processes

We’re eager to show off everything we can do to support you every step of the way through your design process through the finished product. If you have a specific question, ask us directly – we pride ourselves on being able to provide quick answers. Otherwise, here are a few of our favorites:

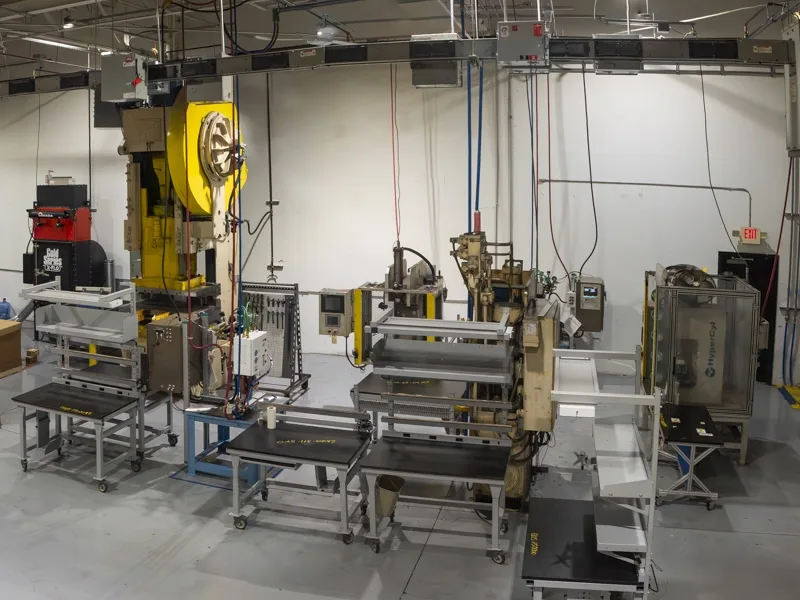

- Stamping: We have a variety of processing paths tailored to suit virtually any part size and volume requirements, all under one roof. We support coil-fed fully automatic transfer, robotic transfer, progressive die and hand transfer. We have more than 30 mechanical and hydraulic presses up to 144” and 800T, and support multi-layer stamping up to 4 layers, including non-metallic insulating layers such as ceramics, fiberglass and polymers for heat shielding applications.

- Die cutting: We have fully automatic coil feed or manual process paths available depending on volume up to 54”, up to 80T.

- Metal embossing: We run up to 48” wide coils of aluminum, steel and stainless steels. We offer patterns to rigidize light-gauge sheet metal and maximize surface area reflecting heat away from components.

- Laminating: We provide a continuous process that can join up to 6 layers, including metals, non-wovens and adhesives, both hot-melt and pressure-sensitive.

- Polymer extrusions: We support twin-screw and single-screw, pelletizing sheet/flat roll products. We also extrude the blowing agent that turns AcoustaDamp™ from a sheet into a foam.

- Laser engraving

- Parts washing

- Ultrasonic welding

- CNC cut

- Automated inspection

- Final inspection and pack

- Assembly: We offer multiple assembly services that support your process through a range of steps, including the following:

- Welding

- Heatstaking

- Riveting (SS and aluminum)

- Pierce nuts

- Weld nuts and studs

- Vibration isolators

- Compression limiters

- Grommets

- Snaps

- Clips

- Push-pins

- Washers

- Materials: We’re ready to work with a wide range of materials, including the following:

- Stainless steels (301, 302, 304, 316, 321, 409 and 439) from 0.003” to 0.125”

- Aluminum from 0.0005” to 0.125”

- Steel (aluminized, hot rolled, cold rolled, high strength) from 0.003” to 0.125”

- Ceramic fiber (paper and blanket formats, with less harmful, non-biopersistant options available) with many chemistries and thicknesses available to tailor solutions across multiple temperature applications.

- Fiberglass (E-Glass and high-temperature rated)

- Non-woven PET, needle-bond and thermally bonded

- Domestic and global material supply chains available

Experience and excellence

Soundwich’s two manufacturing facilities based in Cleveland, Ohio, give us plenty of room for development and production. The Wayside Plant handles the majority of metallic thermal management and metal stampings products. Our St. Clair plant also forms metal heatshields and stampings, but also houses our manufacturing processes for NVH and combination thermal-acoustical products.

Partners in process

Soundwich offers an impressive range of capabilities, but our experienced team makes us so much more than just this list. Our employees exemplify our core values while bringing their skills from a variety of backgrounds to support our clients. Take some time to meet the experts who will work with you in taking your product from design to completion.