We don’t just design and make parts. We show you what’s possible.

Our experienced engineers develop NVH, thermal and underbody solutions that solve complex issues in your most demanding applications.

As your global partner in producing custom-engineered solutions for automotive and aerospace applications, our customer-focused approach blends years of engineering expertise with proven successes.

We advise you at every step of the design process, including material selection, configuration and thickness. Provide the specifications, and we’ll prototype and produce while offering technical knowledge that results in the highest quality and lowest cost.

A partnership of ideas

We commit to supporting you whether we join the project at concept or launch, using experience and new technology to diagnose and solve complex issues. We’re with you every step of the way, supported by our rapid prototyping and testing capabilities. We listen to your feedback and offer expert insights that go beyond only creating a part.

If your application requires OEM-specified materials, we can develop a solution within those boundaries to meet or exceed performance requirements.

What drives our success

Four key concepts support us in providing the best client experience possible and producing high-quality automotive and aerospace parts: Expertise, quality, support and employees.

Our expertise

is what we bring to every interaction from start to finish. We have years of experience paired with robust capabilies to solve complex issues for you. We use new, cutting-edge technology to push the boundaries of what’s possible. As a globally competitive company, we have the resources and capabilities to handle your toughest jobs.

Our quality

is backed-up with a track record of real success shown by data. We listen to you and incorporate feedback to make the best part possible. It’s a part of the company culture that covers every department and process.

Our support

starts from the moment you connect with us, whether that’s at the concept stage or at launch. We cross-functionally collaborate to understand and meet your needs, using our in-house testing and prototyping to quickly and efficiently move the project forward.

Our employees

are the heart of the company, coming from a wide range of backgrounds and experiences. They’re empowered to take ownership of their processes, backed up with certifications and years of industry knowledge. We encourage them to never stop learning, supporting ongoing professional growth and development.

Who we are and where we came from

Founded in 1987, Soundwich started out producing high-quality NVH, thermal and underbody solutions for automotive applications. We showed our expertise in developing a process layering noise-dampening materials efficiently during production, creating the “Soundwich” that gave us our name. As the company has grown, we’ve been recognized globally for our design, prototyping and production accomplishments, connecting with partners throughout the automotive industry. We’ve expanded on those capabilities, setting our sights higher as we work with aerospace partners. Learn more about our company’s history and see how we’ve grown.

Innovative Shielding Systems for Automotive and Aerospace

Our quality products cover a range of NVH, thermal and underbody solutions for automotive and aerospace applications. See some of the ways we can use our expertise to handle your needs, and contact us to share your custom specifications.

ThermaShield™

Features: An ultra-lightweight, multi-layer solution for thermal and acoustic applications, with our largest temperature drop from hot-to-cold side of the heat shield.

KEY BENEFITS:

- Low-mass thermal management solution providing a 750°F temperature drop

- Economical manufacturing with expert support

ThermaPatch™

Features: A versatile, flexible heat-shield option that offers a low-cost solution for areas with some distance between the heat source and the protected component.

KEY BENEFITS:

- Attaches using a pressure-sensitive adhesive

- Versatile design offers quick-fix capability or permanent solutions

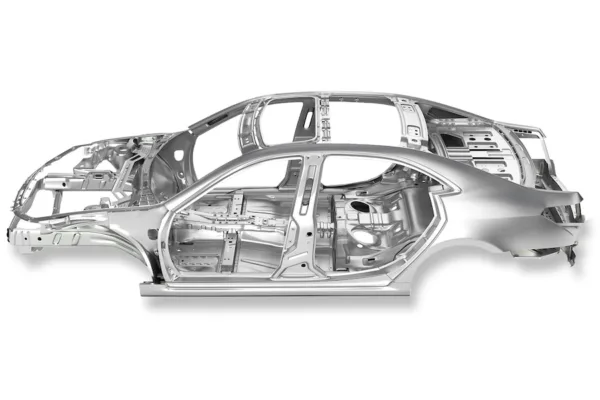

AcoustaDamp™

Features: A constrained layer dampener system that expands during the electro-coat process to ensure complete contact between the body-in-white structure and the constraining layer.

KEY BENEFITS:

- Can be sold as a die-cut sheet or preassembled to a metal constrained layer

- 100% recyclable, localized damping that adds strength and stiffness to panels

Stamping

Features: A variety of processing paths tailored to suit virtually any part size and volume requirements, all under one roof.

KEY BENEFITS:

- Supports coil-fed fully automatic transfer, robotic transfer, progressive die and hand transfer

- Provides expert repair, revision and maintenance for metal stamping tooling systems.

Capabilities

Our experienced, knowledgeable team works with a wide range of new technology and proven processes to deliver results. Learn more about our capabilities to see how we can meet your needs.

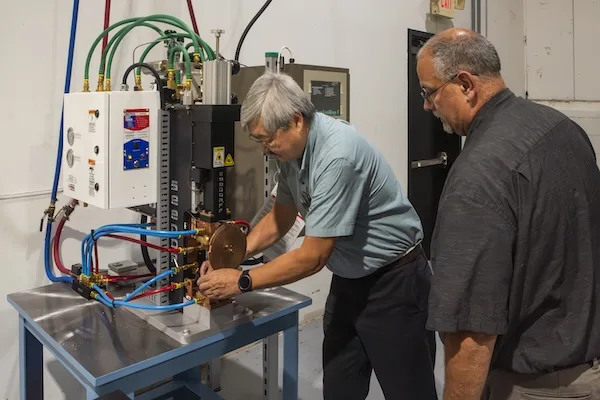

Tooling and prototype

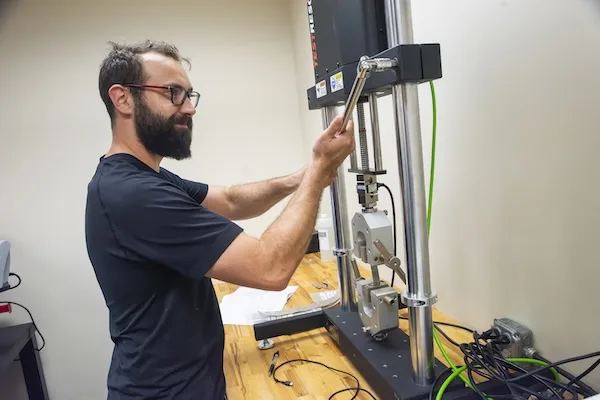

We take pride in our ability to provide rapid prototyping and testing, providing results and incorporating feedback quickly and efficiently. Find out how our speed and quality creates savings for your projects.

Quality assurance

We build quality into our processes from the start with our robust IATF 16949 and AS9100D certified Quality Management System as the foundation. Connect with us to see how we ensure quality every step of the way.

Automotive engineering

Our certified, experienced team has combined decades of automotive industry knowledge, all of which is focused on going beyond just fabricating a part. Learn how our expertise brings higher quality at lower costs.

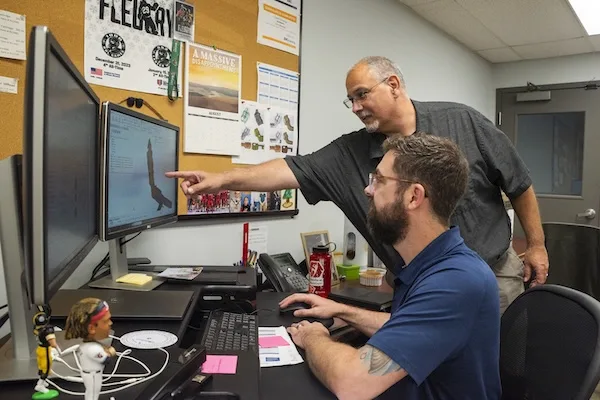

Automotive research and development

We’re always striving to work with new technology and processes to bring you the best options for your project. If we don’t know the answer, we’ll do what we can to help you find it. See how our research drives better results.

Automotive Applications

Our certified team has decades of experience developing, prototyping and completing projects for automotive applications. From concept to launch, we can assist with design, testing and fabrication for applications such as NVH and thermal parts. Learn more about how we can help with automotive projects.

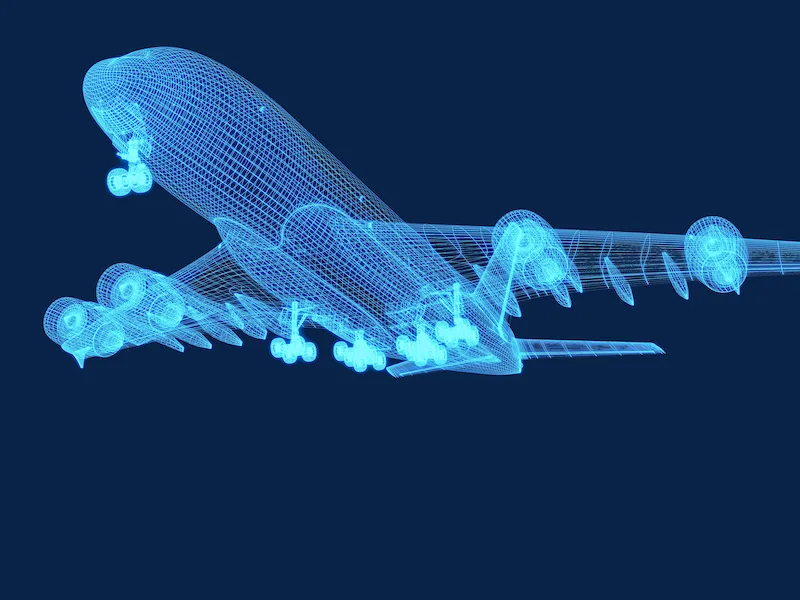

Aerospace Applications

We know that your aerospace applications require special focus and attention. Our experienced team is ready to support you throughout the testing, prototyping and launch phases for applications such as NVH and thermal parts. Learn more about how we can help with aerospace applications.

Soundwich at a glance

Recognized experience

Our team has combined decades of engineering expertise backed up by proven processes. Multiple team members maintain patents, showing their dedication to the industry.

Global reach, focused support

We have a track record of success with automotive and aerospace manufacturers worldwide. Our focused team gives us agility and versatility in meeting your needs, no matter your location or size.

Dedicated to collaboration

We’re ready to cross-functionally collaborate with you, bringing our industry knowledge regardless of what step in the process you’re at. Our team is empowered to take ownership of their work, so every interaction is a chance to make a difference for you.