Custom Designs by Working Shoulder-to-Shoulder with Customers

A customer-centric approach enables our highly skilled team to assist you from the initial development stage to prototype design and final production. Along the way, the Soundwich design team provides technical knowledge that results in the highest quality, yet lowest cost solution.

A partnership of ideas: how we will develop the product.

Working with your product functions and performance concepts, we create a custom design offering a variety of options. We advise you during every step in the process, including material selection, configuration and thickness—all the way to acoustical and thermal performance specifications.

Provide the specs and we will prototype and produce.

If your application requires OEM specified materials, Soundwich can develop a solution within those boundaries to meet or exceed performance requirements. This makes it easy to validate through a proven, rapid-prototyping process.

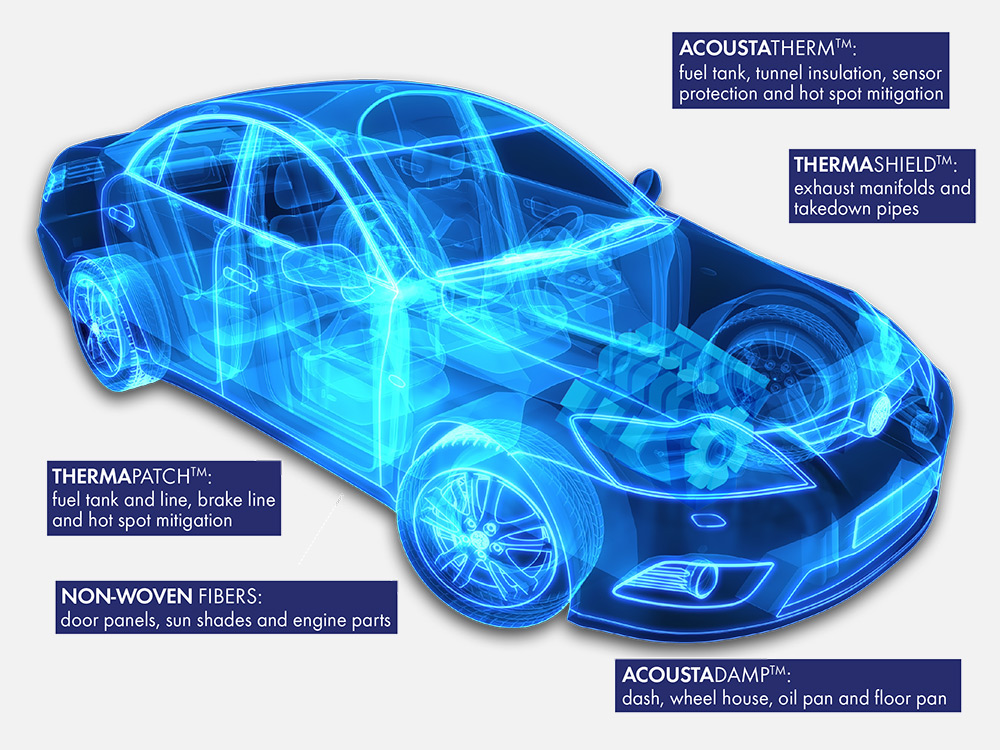

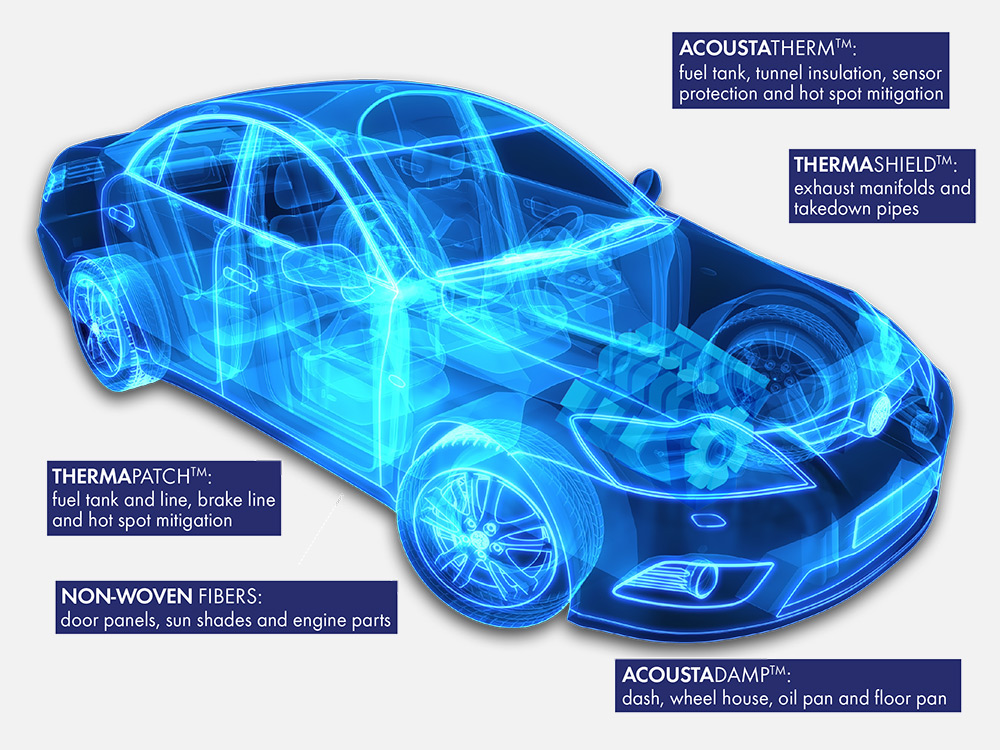

Innovative Shielding Systems

Soundwich is a leading provider of NVH and thermal management products, meticulously manufactured for customers in the transportation, light vehicle, industrial and heavy equipment fields. Founded in 1987, our company has built its reputation as a vertically integrated supplier, providing custom-designed, high-quality workmanship and rapid, on-time delivery to your exacting product specifications.

Ongoing technological expansion at our manufacturing facilities provides improved quality, design flexibility, lower tooling costs, shorter lead times and faster delivery. The result? Your production facilities stay on schedule and on budget.

We work in collaboration with your product engineers and designers to develop solutions that are both cost and mass efficient. We invest heavily in equipment and technical personnel to give you flexible answers to solve your problems. You can be assured of quality components built with accuracy, skill and thoroughness.

Features:

- Provide significant temperature drop in extreme conditions.

- Does not ring or resonate, providing acoustical damping of engine exhaust noise.

- Flexible design and manufacturing process.

Benefits:

- Ideal for direct application onto engine and exhaust.

- Reduces NVH concerns when released in challenging applications.

- ThermaShield can be customized to meet your thermal and cost requirements.

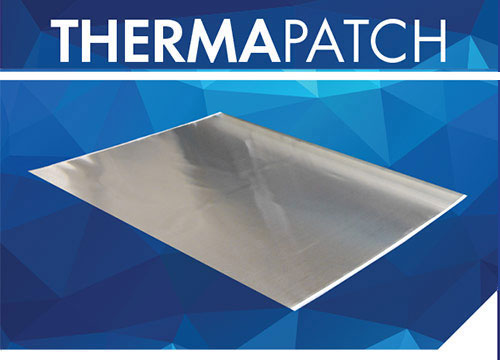

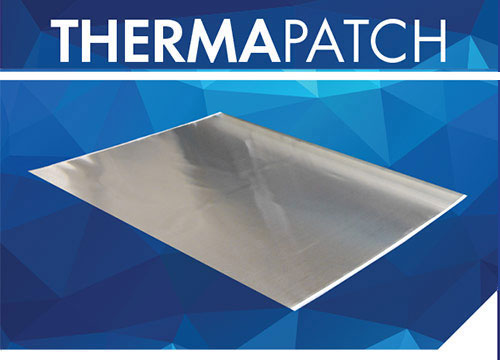

Features:

- Narrow product profile allows usage in areas of limited space.

- Offers radiant heat protection at 350, 450 and 550 C.

- Adhesive systems available to adhere to both metal and HDPE.

- Low-cost and production representative rapid prototypes available.

Benefits:

- Allows usage in areas of limited space.

- Durable construction can survive abuse in engine and exhaust areas.

- Approved adhesive system at all OEMs to adhere to low surface energy plastics.

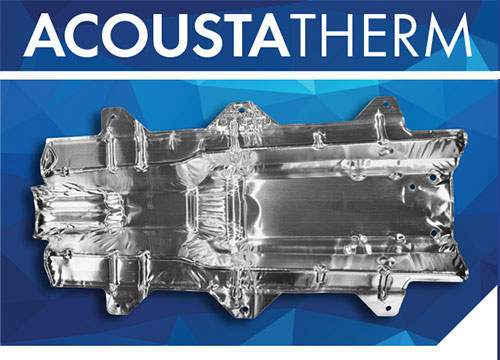

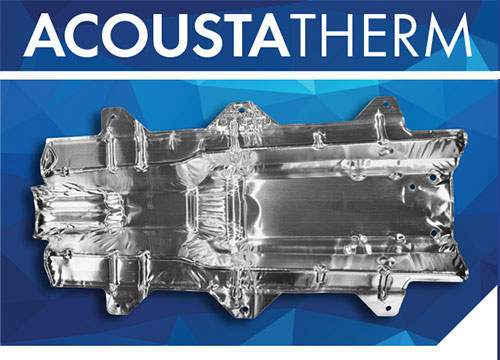

Features:

- Lightweight formable thermal acoustical material.

- Superior acoustic barrier properties.

- Excellent thermal protection system.

- Ability to be customized to meet your specific cost and weight requirements.

Benefits:

- Ideal light weighting option to traditional heatshields.

- AcoustaTherm is ideal for tunnel insulation.

- Due to its low emissivity it reflects heat at a high rate.

- Cost leader in thermal acoustical protection.

Features:

- Up to 250% volumetric expansion.

- High damping rate.

- Increases local stiffness.

- Can be supplied die cut.

Benefits:

- Improves the efficiency of vibrational noise management.

- Allows a surface to be tuned specifically to meet customers damping requirements.

- Lower cost tooling.

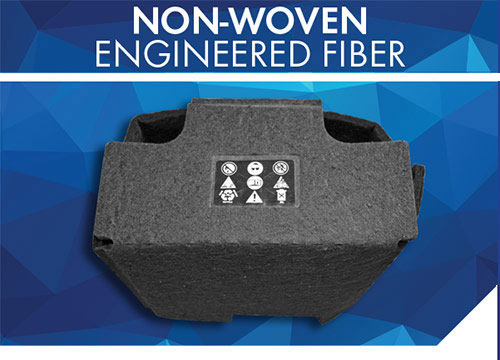

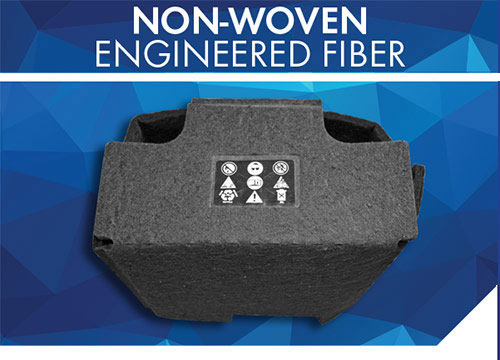

Features:

- Low-cost tooling.

- Short lead times.

- Value-added services: lamination, thermaforming and sonic welding

Benefits:

- Cost-effective, high-performance solutions.

- Produced within the same campus.